2 – Star SR-38 Type B 10 axis Screw machine (With programmable B axis for angular machining on both spindles) up to 38mm diameter barstock in swiss mode, 42mm in chucker mode (New 2016 and 2020)

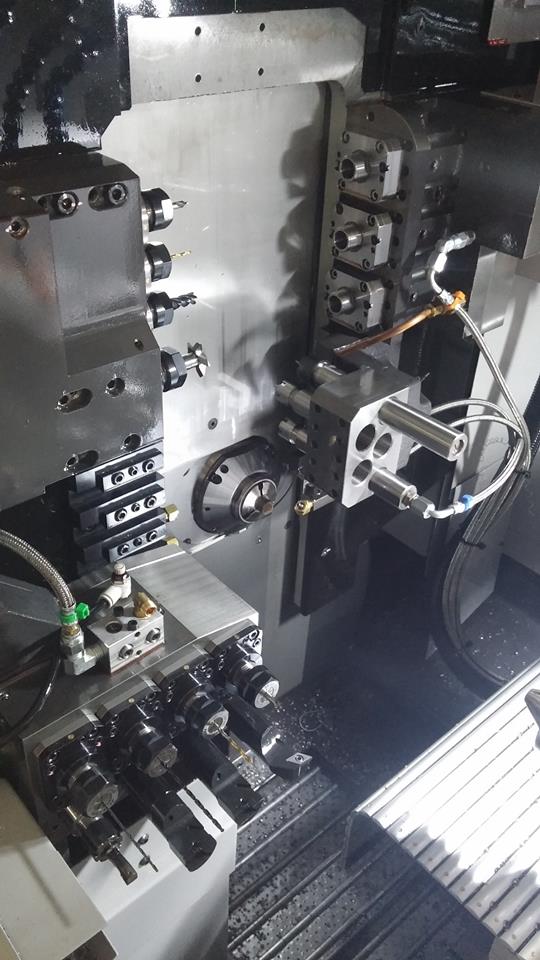

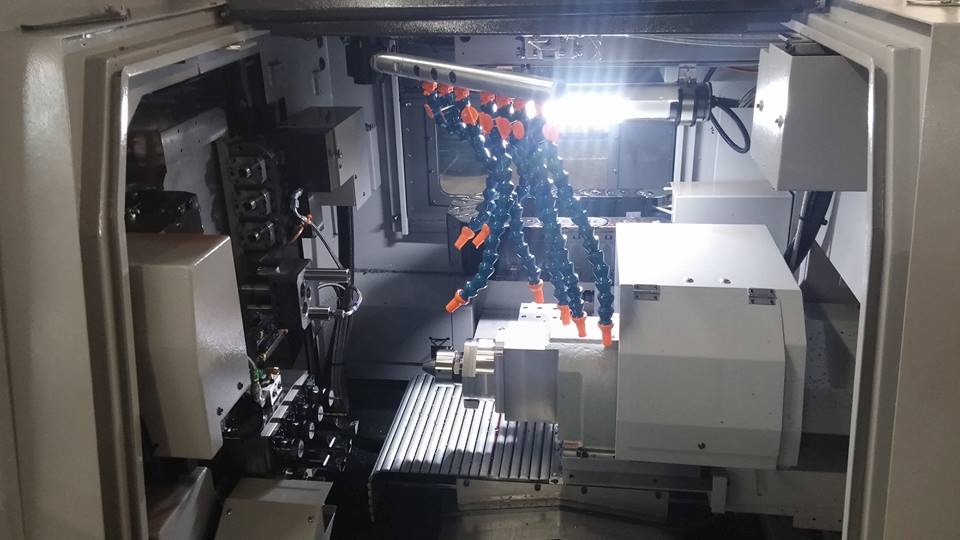

2 – Tsugami B0326-II 8 axis Screw machine up to 32mm diameter bar (New 2015 and 2018)

1 – Tsugami CNC NP-32 6 axis Screw machine up to 1.25 diameter Bar

1 – Tsugami CNC BS-20 7 axis Screw machine up to .812 diameter Bar

1 – Tsugami CNC BS-18 6 axis Screw machine up to .687 diameter Bar

1 – Okuma Cadet LNC-8 2 axis CNC Lathe up to 6″ diameter

1 – Okuma LB-15 2 axis CNC Lathe up to 6″ diameter

1 – Bridgeport Mill

1 – Hardinge lathe

1 – Harig Super 612 Surface Grinder

CNC Milling available off site.

J&L FC-14 Optical Comparator

Quality Management System ISO9001:2008 Compliant

Machine quantities of 1pc -1 Million +

Can repeat tolerances of +/-.0001

Can machine the following materials:

Aluminum – All grades

Stainless Steel – 300 Series, 400 Series, 17-4, 15-5 and most others

Alloy Steels – 4130, 4140, 4130, 4150, 8620, 52100, 8740 and most others

ToolSteels – A-2, D-2, A-6, 0-1, CPM

Steels – 1018/1020, 12L14, 1117, 1045, A36

Specialty Steels – Maraging, Vasco Max, Flexor M

Plastics – Acetal, Nylon, Phoenolic, Most others

Nickel alloys and high temp alloys, Electromagnetic Iron

Titanium

Can provide outside services including but not limited to:

Heat Treatment, Anodize, Paint, Passivation, Chrome, Nickel, Electroless Nickel, Bead Blasting, Welding, Grinding, Wire EDM, Cadmium, Silver, and Gold.

Building – 3200Sq FT Employees – 6